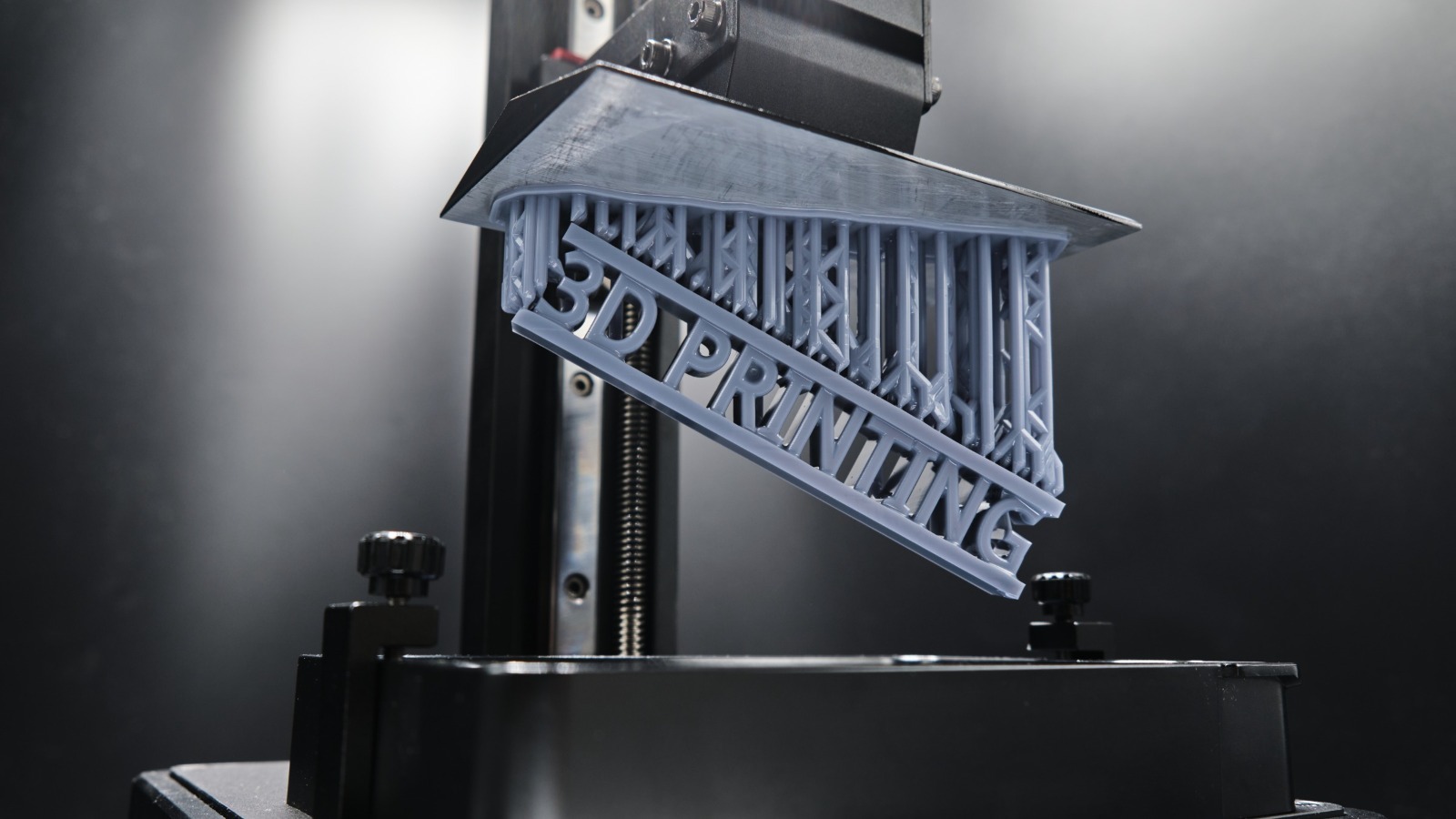

Second-hand resin printers are significantly attractive in terms of price, especially for individual makers, small studios or educational institutions with limited budgets who hope to enter the resin printing field quickly. Second-hand resin printers have the potential advantages of low entry barriers and high cost performance.

However, the core cost of resin printers is not merely the purchase price, but also includes subsequent consumables, maintenance, parts replacement and safety compliance costs. Second-hand equipment often conceals potential risks: aging of the light source, decline in the sealing performance of the box, deterioration of the stability of the UV curing system, contamination risks caused by the chemical residue on the UV cover/frame, as well as whether the software and firmware updates and support are in place, etc. Therefore, a comprehensive assessment of the device’s status, historical usage scenarios, and subsequent support capabilities is the key to deciding whether to purchase a second-hand 3D printer.

Used Resin Printer’s Value and Target Audience

Second-hand resin printers are suitable for start-up small studios or individual makers who wish to test the water of resin printing at a lower cost, quickly iterate prototypes or produce small batches of high-precision items. The first choice is in educational institutions and training environments, where it is used for course demonstrations and student practices. It is cost-sensitive and has a certain tolerance for equipment reliability.

Secondly, there are enthusiasts with self-maintenance capabilities. They are willing to maintain and upgrade the system by themselves and have a certain level of familiarity with consumables and post-treatment processes. The potential to achieve high detail and surface finish with a relatively low initial investment, when combined with a reasonable post-processing equipment and material ecosystem, can still lead to considerable output efficiency. Compared with a new 3D printer, the cost-performance advantage of a second-hand 3D printer comes from significant price discounts, but it is predicated on verifiable availability and sustainable follow-up support.

Critical Risks and Mitigation Strategies

The primary risks associated with used equipment center on the degradation of the light source and mechanical systems. The aging of the light engine can lead to intensity attenuation and uneven exposure, which directly compromises layer consistency and detail retention, ultimately reducing process repeatability. To mitigate this, prospective buyers should conduct actual print tests—specifically targeting both high-detail zones and large flat areas—and request documentation regarding any light source replacements or calibration. Simultaneously, mechanical wear on drive shafts, guide rails, film sensors, and tilt mechanisms can introduce alignment errors, layer shifts, or adhesion failures. It is crucial to verify the machine’s total runtime, review the most recent maintenance logs, and check for a history of component replacement; budgeting for potential mechanical overhaul is often necessary.

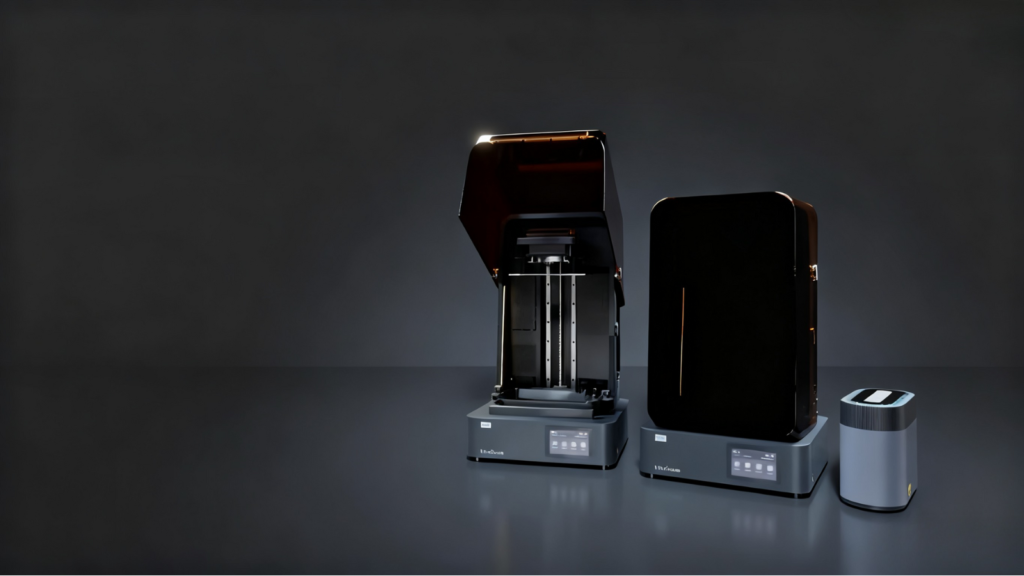

Beyond hardware, the material ecosystem and software compatibility present significant variables. Certain second-hand machines may have regional restrictions on material brands or require specific resin batches to ensure performance. It is vital to confirm the availability of the official or certified material supply chain for the specific model in question. For example, integrated ecosystems like those found in HeyGears 3D printers are designed for specific resin parameters; ensuring you can still access these validated workflows is essential for safety and quality. Additionally, risks regarding obsolete firmware or discontinued manufacturer support can leave users without necessary slicing parameters or calibration tools. Buyers should prioritize models that still enjoy market support or have active community-driven firmware updates, while also strictly evaluating the equipment against current safety compliance standards—specifically ventilation, waste containment, and seal integrity—to ensure the workspace remains safe.

Assessment Checklist: A Systematic Pre-Purchase Inspection

A systematic pre-purchase inspection should function as a comprehensive audit of the machine’s physical and digital state. Begin by examining the exterior and core components: ensure the casing seals are intact, the viewing window is free of cracks, the guide rails move smoothly, and the build platform is stable. Crucially, assess the light source for uniformity and acceptable brightness, check the condition of the LCD or projection screen, and look for significant wear on transmission parts. The machine’s usage history provides context for these physical observations; attempt to acquire the manufacturing date, total operating hours, and a log of recent maintenance or failure resolutions.

The assessment must then extend to software and safety. Verify the compatibility of available slicing software versions, check if the machine requires binding to a specific user account, and confirm the availability of future firmware updates. It is equally important to evaluate the post-processing and safety ecosystem: determine if the unit comes with original or certified washing and curing equipment, a clear waste disposal plan, and compliant user manuals. Finally, a rigorous cost analysis should move beyond the purchase price to estimate the Total Cost of Ownership (TCO), factoring in consumables, filtration replacements, and potential repair costs to determine the true return on investment.

Selection Strategies and Scenario-Based Recommendations

Selection strategies must be strictly tailored to the specific application scenario. If the objective is high-precision work, such as jewelry casting patterns or pre-clinical medical models, the stability of the light source and resolution is non-negotiable. In these high-stakes scenarios, acquiring a used unit from a premium brand like HeyGears—known for its durable, industrial-grade architecture—is often safer than buying a generic hobbyist machine, provided the material ecosystem is still accessible. However, if the equipment is too old or unsupported, the risk is likely too high. Conversely, for educational demonstrations or entry-level rapid prototyping where slight variations are acceptable, users can tolerate more fluctuation and maintenance, provided there are sufficient community resources to support troubleshooting.

Financially, a prudent approach involves allocating a specific portion of the total budget for the first year’s operational needs, including resins, cleaning agents, and replacement parts, to prevent cost overruns. When negotiating, prioritize reputable secondary markets or dealers who offer clear after-sales commitments and retain complete transaction records. Wherever possible, secure a trial period or a limited warranty to define liability for potential failures, ensuring that the acquisition does not become a liability due to hidden defects.

Implementation Path: From Used Purchase to Stable Operations

Transitioning from a used purchase to stable operations requires a structured implementation path, starting with a rigorous trial plan. Before the purchase is finalized or immediately upon receipt, execute a specific evaluation protocol that includes printing sample parts, testing various materials, and verifying dimensional stability and repeatability; these results should serve as the final basis for decision-making. Once the equipment is onboarded, immediate attention must be given to establishing post-processing and process standards. Whether utilizing existing equipment or a custom workflow, standardizing these steps is critical for consistency.

Furthermore, the team must be systematically introduced to the equipment through training that covers the specific quirks of the used machine, material safety data, and basic maintenance skills. This training is essential to mitigate the production risks associated with equipment aging. Finally, a risk mitigation and exit strategy should be in place: set clear budget caps and timelines. If the machine displays unmanageable instability or if maintenance costs exceed the projected buffer, the organization must be prepared to adjust its strategy or decommission the unit to protect overall productivity.

Conclusion: Is a Used Resin Printer Worth the Investment?

Ultimately, the decision to purchase a used resin printer hinges on the balance between budget constraints and technical capability. It is a worthy investment when the budget is limited, but only if the buyer enforces strict acceptance standards and possesses strong internal management and maintenance capabilities. Through systematic assessment, rigorous testing, and careful planning of the post-processing and material ecosystem, a used machine can offer a high cost-performance ratio for entering the field of high-precision printing. However, one should not be overly optimistic; if the application relies heavily on a cutting-edge material ecosystem or demands uncompromising stability and safety, the hidden costs and potential failure risks of used equipment may eventually exceed the cost of a new machine, particularly when the continuity of technical support cannot be guaranteed.