In today’s manufacturing world, precision, efficiency, and durability are non-negotiable. Companies across industries — from automotive to medical and consumer electronics — rely on plastic injection molders to deliver parts that meet exacting standards. Behind every successful component lies a carefully designed injection mold and a highly refined injection molding process.

At Rapid Molding, we understand that the key to creating high-quality plastic parts is mastering both the art and science of injection molding molds. From mold design to material selection and process optimization, every step plays a vital role in achieving flawless, durable products.

Understanding the Role of Plastic Injection Molders

Plastic injection molders are specialized manufacturers that produce plastic components using a process known as injection molding. This technique involves melting thermoplastic material and injecting it into a precision-engineered injection mold, where it cools and hardens into a specific shape.

The process is fast, efficient, and capable of producing millions of identical parts with incredible accuracy. However, achieving top-quality results depends on several critical factors: the design of the mold, the type of material used, and the precision of the machinery operating it.

The Importance of the Injection Mold

The injection mold is the foundation of every successful molding project. It determines not only the shape of the final part but also its surface finish, dimensional accuracy, and overall strength.

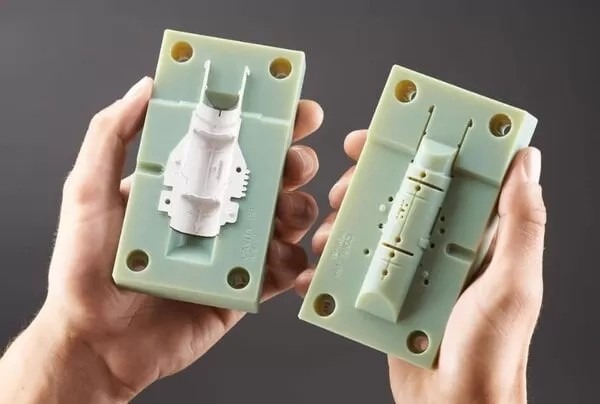

A well-built mold consists of two main halves — the cavity and the core — which come together during the molding process. When molten plastic is injected into the cavity, it fills every detail of the design. After cooling, the part is ejected, and the cycle repeats.

Each injection mold must be designed to withstand high pressure and temperature while maintaining tight tolerances. Poor mold design can lead to issues like warping, uneven surfaces, or short shots (incomplete filling). That’s why top manufacturers like Rapid Molding invest in advanced CAD/CAM technology to simulate and perfect the mold design before production begins.

Designing High-Precision Injection Molding Molds

Design is the most critical stage of injection molding molds development. It’s where engineering expertise meets creativity to turn an idea into a manufacturable component.

A professional mold design takes into account:

- Material flow and cooling: Proper gating and cooling channels ensure even filling and prevent warping or shrinkage.

- Ejection systems: Designed to remove parts without leaving marks or causing damage.

- Mold material selection: Steel and aluminum are most common, with steel preferred for high-volume production due to its durability.

- Tolerance control: Precision machining ensures each part is dimensionally accurate and repeatable.

At Rapid Molding, our mold engineers use advanced simulation software to analyze how molten plastic will flow inside the mold. This predictive modeling helps identify potential issues early — such as air traps, sink marks, or uneven cooling — resulting in perfectly balanced injection molding molds that produce superior parts.

Material Selection for Durability

The choice of plastic material has a significant impact on the quality and longevity of molded parts. Each polymer behaves differently during molding, and selecting the right one depends on the intended application.

For example:

- ABS (Acrylonitrile Butadiene Styrene) offers excellent toughness and impact resistance.

- Polycarbonate provides clarity and strength, ideal for transparent components.

- Nylon delivers flexibility and abrasion resistance, suitable for gears and mechanical parts.

- Polypropylene (PP) is lightweight and chemical-resistant, making it a common choice for packaging and automotive applications.

Experienced plastic injection molders like Rapid Molding help clients select materials that balance cost, performance, and durability — ensuring each part functions reliably under real-world conditions.

The Injection Molding Process: Step-by-Step

Creating durable, high-quality plastic parts involves a series of precisely controlled steps:

1. Clamping

The two halves of the injection mold are securely closed by a clamping unit. This ensures no material escapes during injection.

2. Injection

Molten plastic is injected into the cavity at high pressure, filling every corner of the mold. The flow rate and pressure must be perfectly balanced to prevent air bubbles or incomplete filling.

3. Cooling

Once filled, the molten material begins to cool and solidify within the mold. Cooling time is crucial — too fast, and the part may shrink; too slow, and production efficiency suffers.

4. Ejection

After the part has solidified, it’s carefully ejected from the mold. The cycle then repeats, often within seconds.

These steps are automated in modern injection molding machines, allowing for consistent output and minimal variation across thousands of cycles.

Quality Assurance and Precision Control

Producing durable, high-quality parts requires more than just good machinery — it demands rigorous quality control. At Rapid Molding, we use real-time monitoring systems to track temperature, pressure, and cycle times during every molding run.

Each batch undergoes thorough inspection for:

- Dimensional accuracy

- Surface finish

- Structural integrity

- Material consistency

By maintaining strict process control, we ensure that every part coming out of our injection molding molds meets exact specifications.

Advantages of Working with Expert Plastic Injection Molders

Partnering with an experienced molding company offers several benefits:

- Consistency: Every part produced is identical, even across high-volume runs.

- Efficiency: Automated systems minimize waste and reduce production costs.

- Customization: Tailored injection molds can produce complex geometries and fine details.

- Durability: Proper material selection and design lead to parts that last longer under stress.

- Scalability: Whether producing prototypes or millions of components, injection molding supports any production scale.

At Rapid Molding, our commitment to precision engineering, modern equipment, and continuous innovation ensures your products perform at the highest level.

Innovation in Injection Molding Technology

Recent advancements are revolutionizing how plastic injection molders operate. Techniques like multi-cavity molds, hot runner systems, and conformal cooling channels are improving efficiency and reducing cycle times.

Additionally, digital twins and AI-driven monitoring systems allow for predictive maintenance of injection molding molds, reducing downtime and increasing productivity. These technologies enable manufacturers to meet growing demands for faster, more sustainable production.

Conclusion

Creating durable, high-quality plastic parts is both an art and a science. It requires expertly crafted injection molds, advanced injection molding equipment, and a team of experienced professionals who understand every detail of the process.

At Rapid Molding, we bring all these elements together — combining precision engineering with cutting-edge technology to deliver results that exceed expectations. Whether you need prototypes, small batches, or mass production, our plastic injection molders ensure superior quality and durability with every part we produce.

When precision matters, trust Rapid Molding — where every injection mold is built to perform, and every molded part is made to last.