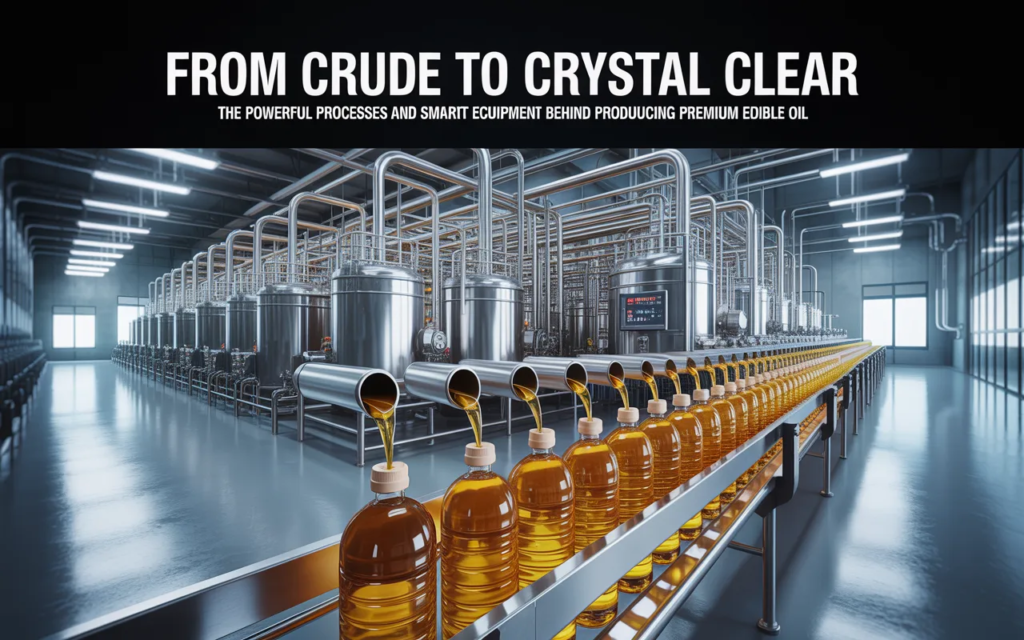

Edible oil is something most people use without thinking. It’s in our kitchens, restaurants, bakeries, and food factories. Yet few ever see what oil looks like before it becomes that clear, golden liquid on the shelf.

In its raw state, oil is far from perfect.

Crude oil pressed from soybeans, sunflower seeds, peanuts, palm fruit, or rapeseed is thick, dark, and unstable. It carries strong odors, cloudy particles, free fatty acids, waxes, and pigments. If you’ve ever seen unrefined oil in a processing plant, you’ll understand immediately—it simply isn’t suitable for food.

This is where refining changes everything.

Through advanced machinery and carefully controlled steps, crude oil is transformed into something clean, stable, and safe. Behind this transformation are professional manufacturers like GQ-Agri, a leading agricultural machinery manufacturer from China, committed to helping farmers and processors turn raw crops into higher-value products.

Why Crude Oil Must Be Refined

Crude oil is rich in nutrients—but also full of unwanted compounds. These include:

- Gums and phospholipids

- Free fatty acids

- Pigments and waxes

- Odor and flavor compounds

If left untreated, this oil:

- Spoils faster

- Smells unpleasant

- Looks dark or cloudy

- Smokes at lower temperatures

Refining removes these problems and unlocks the oil’s full potential. It improves shelf life, flavor, color, and safety. That is why every serious oil producer depends on modern refining systems.

The Core Refining Stages That Transform Oil

The journey from crude to crystal-clear oil follows a precise sequence known as the Edible oil refining process – degumming, deacidification, decolorization, and deodorization.

Each step quietly solves a problem that would otherwise ruin the final product.

1. Degumming – Clearing the First Impurities

Degumming removes phospholipids, trace metals, and gums that cause haze and poor storage stability. Water or acid binds these compounds so they can be separated. This step is the foundation—without it, the next stages cannot work properly.

2. Deacidification – Balancing Flavor and Stability

Free fatty acids create off-flavors and shorten shelf life. Deacidification neutralizes or separates these acids, making the oil smoother, safer, and more stable.

3. Decolorization – Creating a Clean Appearance

Pigments like chlorophyll and carotenoids darken crude oil. Bleaching earth or activated carbon absorbs these colors, leaving the oil bright and visually appealing.

4. Deodorization – Delivering a Neutral Taste

This final step removes odors and volatile compounds under high temperature and vacuum steam. The result is oil that smells clean, tastes neutral, and performs consistently in cooking.

Smart Equipment Makes Refining Possible

These processes require precision. Temperature, pressure, and timing must be controlled perfectly. That’s why producers rely on advanced machinery and carefully engineered systems.

Manufacturers provide different Edible Oil Refining Equipment Types to match the scale of production—from small workshops to large industrial plants.

Common Equipment in a Refining Line

A complete system may include:

- Degumming reactors

- Neutralization tanks

- Bleaching vessels

- Deodorization towers

- Heat exchangers

- Vacuum systems

- Filtration units

Together, these machines ensure smooth, hygienic, and continuous refining.

The Role of GQ-Agri in Modern Oil Refining

GQ-Agri believes that small-scale farming should not mean small-scale profits. As a leading agricultural machinery supplier from China, the company designs affordable, durable, and easy-to-use equipment for global producers.

Their refining systems are built with:

- Energy-efficient designs

- Simple, user-friendly controls

- Strong industrial materials

- Easy maintenance access

This allows even growing businesses to operate with professional-level technology.

Batch vs. Continuous Refining

Producers can choose between:

Batch systems

- Ideal for small to medium volumes

- Lower startup cost

- Flexible for different oils

Continuous systems

- Best for large-scale production

- Fully automated

- Lower cost per ton

The right choice depends on volume, oil type, and long-term goals.

Sustainability and Safety

Modern refining equipment recovers heat, reduces waste, and lowers energy use. It also ensures hygienic processing that meets global food safety standards—protecting both consumers and businesses.

Final Thoughts

The journey from crude oil to premium edible oil is one of precision, technology, and experience. Through the Edible oil refining process – degumming, deacidification, decolorization, and deodorization, raw oil becomes clean, stable, and safe.

With advanced Edible Oil Refining Equipment Types and the support of manufacturers like GQ-Agri, producers can achieve higher quality, stronger efficiency, and long-term success—proving that smart machinery truly turns raw crops into valuable products.